Corrosion Coupon Racks: How They Work & Why They Matter

Keeping a close eye on the condition of pipelines is critical for the oil and gas sector. In an industry where a single leak can cause catastrophe, knowing exactly how likely a particular segment of piping is to fail ahead of time is worth its weight in gold. This is why corrosion coupon racks are essential equipment for operators within the energy sector. If you’re unfamiliar with corrosion coupon holders and how they work, you may be unknowingly putting your infrastructure at significant risk of failure. Read on to learn more about what a corrosion coupon holder is and what makes it so vital.

How Corrosion Coupon Racks Work

A corrosion coupon is a small strip of metal made of the same materials as the pipeline. Its purpose is to allow pipeline operators to track the galvanic corrosion rate within the system without inspecting all the piping from the inside. By exposing the coupons to the same conditions as inside the pipeline, operators can observe how quickly the metal begins to corrode. This enables the operators to make informed decisions about maintenance and repairs before corrosion has a chance to impact actual production.

A corrosion coupon rack is a simple assembly that is connected to process piping. It consists of multiple pipes containing coupons, through which the same fluids inside the pipeline flow. After a certain amount of time, the coupons are removed from the rack and sent to a laboratory for analysis.

The Importance of Corrosion Monitoring

Corrosion coupon racks are crucial in the oil and gas industry, where operators need to protect and preserve the lifespan of their infrastructure for as long as possible. Based on the results of the lab testing on the coupons, companies can plan for maintenance and repairs without resorting to guesswork. They will know exactly how the materials within the pipelines are holding up under the conditions without needing to perform time-consuming and costly inspections.

Key Considerations for Corrosion Coupon Testing

Getting the best results from corrosion coupon testing means being strategic about the placement of your racks. For example, installing them too close to a major source of heat will accelerate the rate of corrosion on the coupons and skew the results. On the other hand, placing it too close to a cooling tower will have the opposite effect and result in corrosion rates that are too slow.

Operators also need to be careful when handling coupons, being sure not to touch them with bare hands. The oils on human skin can affect the rate at which the coupons corrode, as can any contaminants that enter the process pipelines.

Frequently Asked Questions (FAQs)

What is the purpose of a corrosion coupon rack?

A corrosion coupon rack is used to monitor the rate of corrosion within a pipeline system by exposing metal test strips (coupons) to the same conditions as the pipeline. These racks allow operators to assess the impact of corrosion without inspecting the entire pipeline, enabling proactive maintenance and preventing costly failures.

What is the corrosion coupon procedure?

The corrosion coupon procedure involves placing metal coupons into a coupon rack that is connected to process piping. These coupons remain in the system for a set period, during which they experience the same environmental conditions as the pipeline. After the exposure period, the coupons are removed and analyzed in a laboratory to determine the extent of metal loss, which helps operators evaluate corrosion rates and adjust maintenance strategies accordingly.

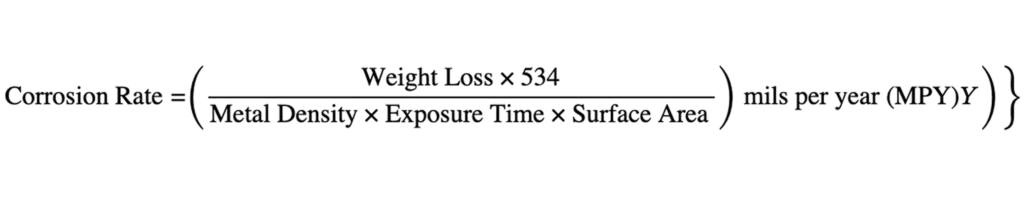

How do you calculate the corrosion rate of a coupon?

The corrosion rate of a coupon is calculated using a standard formula that factors in the weight loss of the coupon over time, the density of the metal, and the total exposure duration. This measurement is typically performed in a laboratory setting to ensure accuracy. The formula commonly used is:

What is a corrosion coupon in an oil field?

In an oil field, a corrosion coupon is a small metal strip made of the same material as the pipeline, designed to measure corrosion rates in production and transportation systems. By placing these coupons in corrosion coupon racks, operators can track how environmental factors such as pressure, temperature, and chemical composition affect pipeline integrity. This information is crucial for maintaining infrastructure reliability and preventing failures.

How SMARTCORR® Can Help

As a leader in corrosion monitoring solutions for the oil and gas sector, SMARTCORR® provides you with everything you need to watch over the health of your pipeline systems. In addition to corrosion coupon racks, we also provide corrosion coupon retrieval tools to enhance the safety and efficiency of your operations. To learn more about these products and all other services we can deliver for you, reach out and speak with a member of our team today.