How a Chemical Injection Quill Boosts Asset Longevity

Protecting pipeline assets is of the utmost importance in the oil and gas sector, which is why so many operators introduce chemical corrosion inhibitors into their process flow. But simply adding these chemicals into the pipeline may not be enough. Using chemical injection quills provides the control and precision necessary to ensure pipelines receive the correct dosing and maximum protection. Read on to learn more about what makes chemical injection quills so important for asset integrity and longevity.

Benefits of Using a Chemical Injection Quill

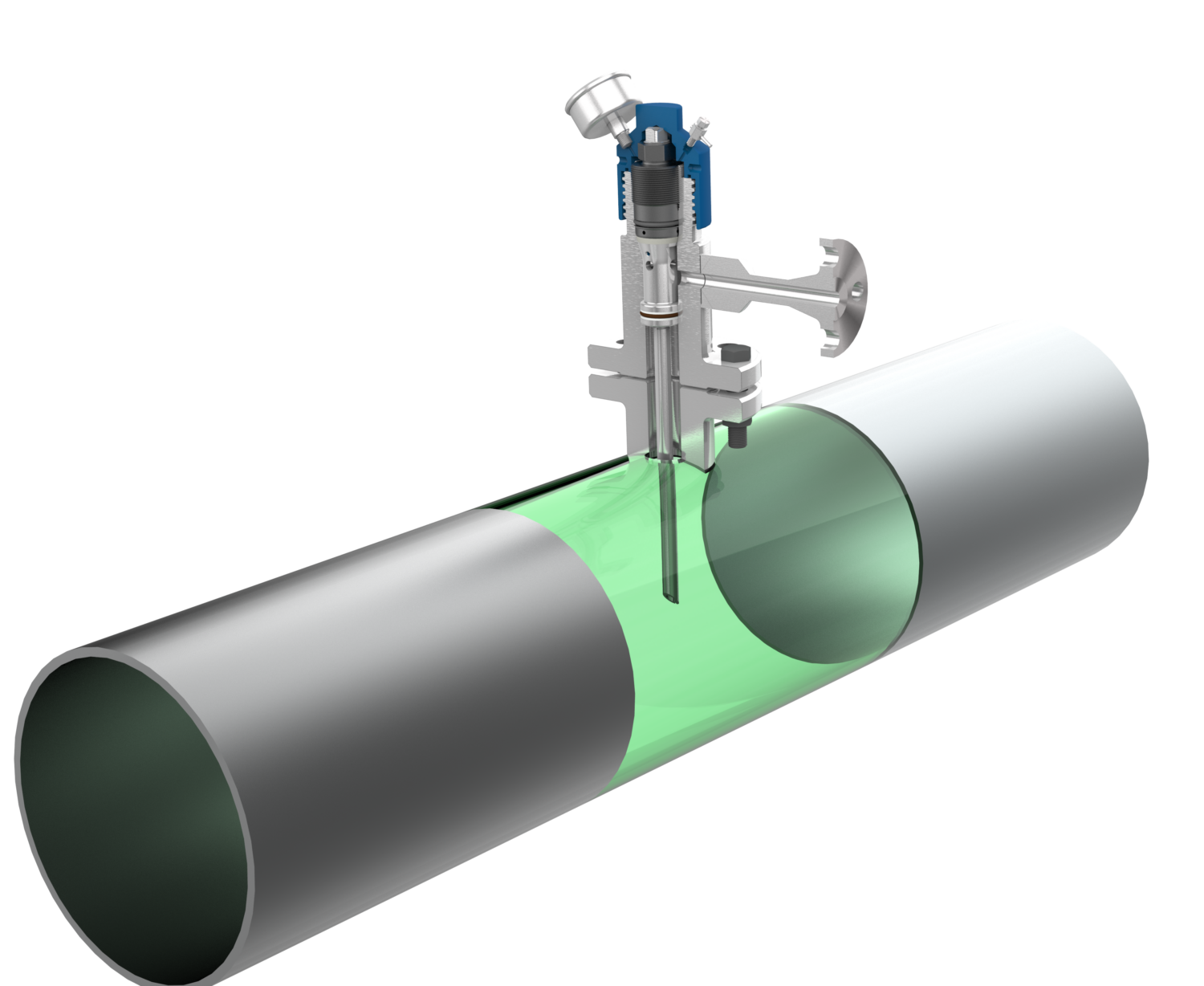

An injection quill is inserted into a strategic spot along the pipeline, where it releases a carefully controlled amount of a fluid into the process stream. It usually has several holes in the body of the quill to ensure even distribution of the chemical.

Using chemical injection quills is key for a number of reasons, most of which have to do with ensuring the longevity and performance of pipeline assets. Because they are designed to release fluids directly into the center of the pipeline, they prevent chemicals from sticking to the sides of the pipe. This means they can be essential tools for preventing corrosion that can lead to failures. Additionally, they help provide a more homogenous mix of chemicals inside the stream by controlling the release and ensuring the chemicals are dispersed in the optimal manner.

Types of Chemical Quills and Applications

There are many different varieties of quills to suit specialized applications in the oil and gas sector as well as other industries. The two main categories these typically fall into are retractable and non-retractable. Retractable chemical injection quills are designed to be removed from the process stream, while the latter are intended to be permanently installed in the pipeline for regular use.

Depending on the use case, quills may require specific specifications. For example, those used within high-pressure injection systems typically feature robust construction with high-grade alloy materials to ensure their performance under intense conditions. Other options may include different hole or spray nozzle placement for different flow rates, specific materials for temperature resistance, and designs intended for compatibility with specific chemicals.

Best Practices for Installing and Maintaining Injection Quills

Proper installation and maintenance are key for getting the most performance from a chemical injector quill. They should be installed in locations where they will provide the optimal mixture of chemicals within the stream and also will be easy to access for maintenance. They need to be properly tightened to prevent leaks, and technicians should inspect and clean them on a regular schedule according to the manufacturer’s recommendations.

Why Choose SMARTCORR® for Injection Quill Solutions?

As the global leaders in corrosion prevention technology for the oil and gas sector, SMARTCORR® delivers proven chemical injection solutions. Our engineering and research capabilities enable us to bring the systems clients need to extend the longevity of their assets and maintain the highest levels of productivity. Choosing us also means operators gain ongoing support and technical consultation from our knowledgeable experts. To learn more about our full range of injection and sampling systems, follow the link or reach out to one of our team members today.