The Importance of a Corrosion Monitoring System

Oil and gas companies need to be aware of how the corrosive environments they work in affect their equipment. Because plants and the machinery they use represent a sizable investment, it is critical to keep an eye on internal corrosion before it causes irreparable damage. A real-time corrosion rate monitoring system is exceptionally valuable because it determines how corrosive the surrounding environment is and tracks the rate of metal loss experienced by assets within the area.

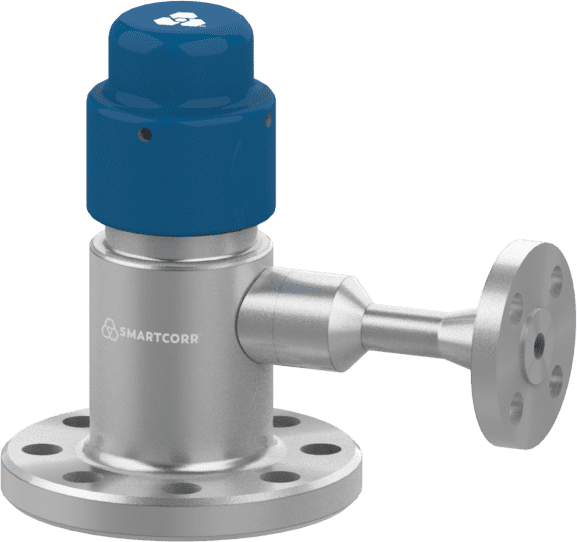

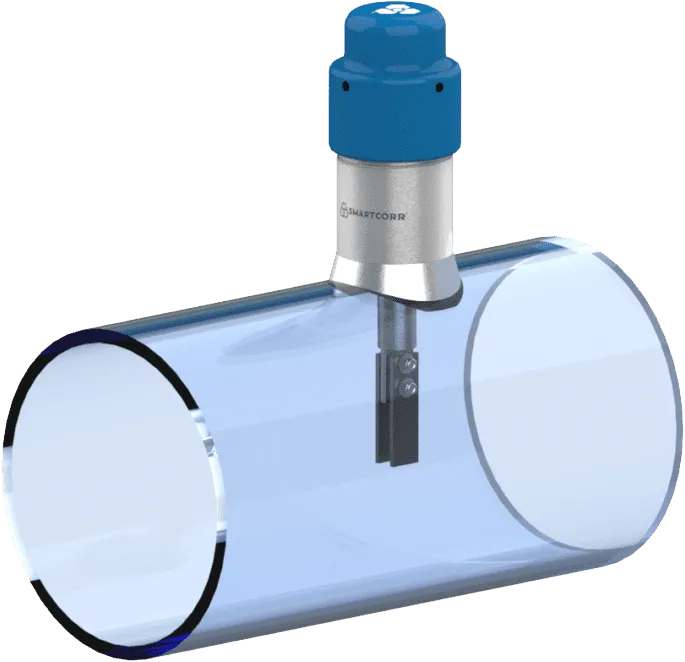

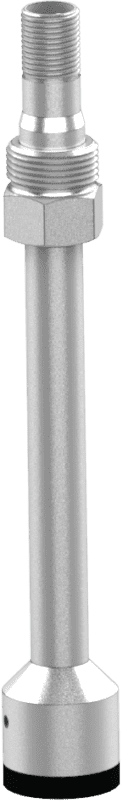

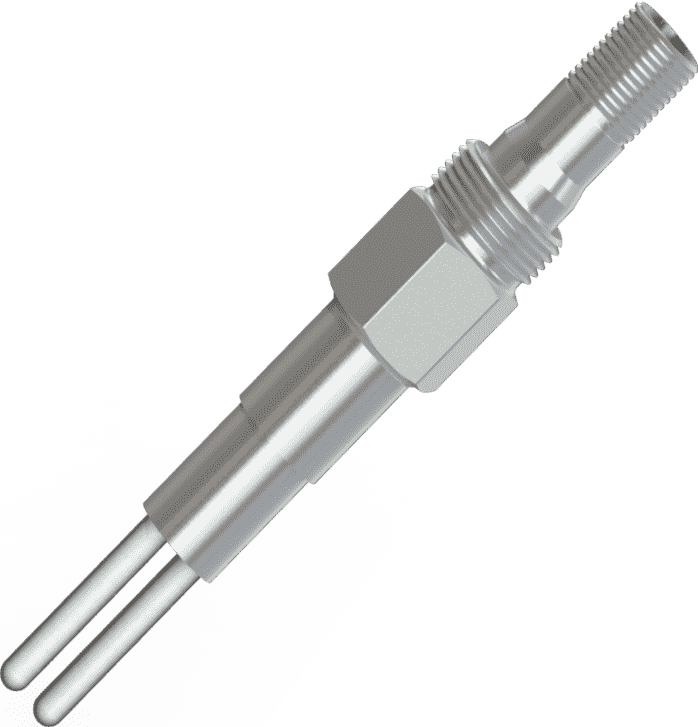

There is a wide range of technologies typically employed in a corrosion monitoring system for pipelines and other assets, all working together to provide the most accurate picture of how equipment fares in a particular environment. Pipeline corrosion monitoring probes, sensors, and other elements need to be capable of providing accurate and reliable results each time they are used.

This is why so many in the industry turn to SMARTCORR® for an internal corrosion monitoring system.