CORROSION MONITORING SYSTEM

Oil and gas companies need to be aware of how the corrosive environments they work in affect their equipment. Because plants and the machinery they use represent a sizable investment, it is critical to keep an eye on corrosion before it causes irreparable damage. Real-time corrosion monitoring system is exceptionally valuable because it determines how corrosive the surrounding environment is and tracks the rate of metal loss experienced by assets within the area. There is a wide range of technologies typically employed in a corrosion monitoring system for pipelines and other assets, all working together to provide the most accurate picture of how equipment fares in a particular environment. Corrosion monitoring probes, sensors, and other elements need to be capable of providing accurate and reliable results each time they are used.

This is why so many in the industry turn to SMARTCORR® for corrosion monitoring system. The SMARTCORR Corrosion Monitoring System is a proactive solution to assist with operating a plant more effectively, thereby prolonging its life and gaining optimum throughput. It also enables continuous monitoring of actual corrosion rates, allowing for timely preventative action if a variance is observed. As part of our integrated asset integrity management services, our corrosion monitoring solutions provide our customers with the detailed, accurate data they need to make informed decisions about maintenance and protecting their systems. They know they can trust us because of our extensive expertise and innovative approach to corrosion protection.

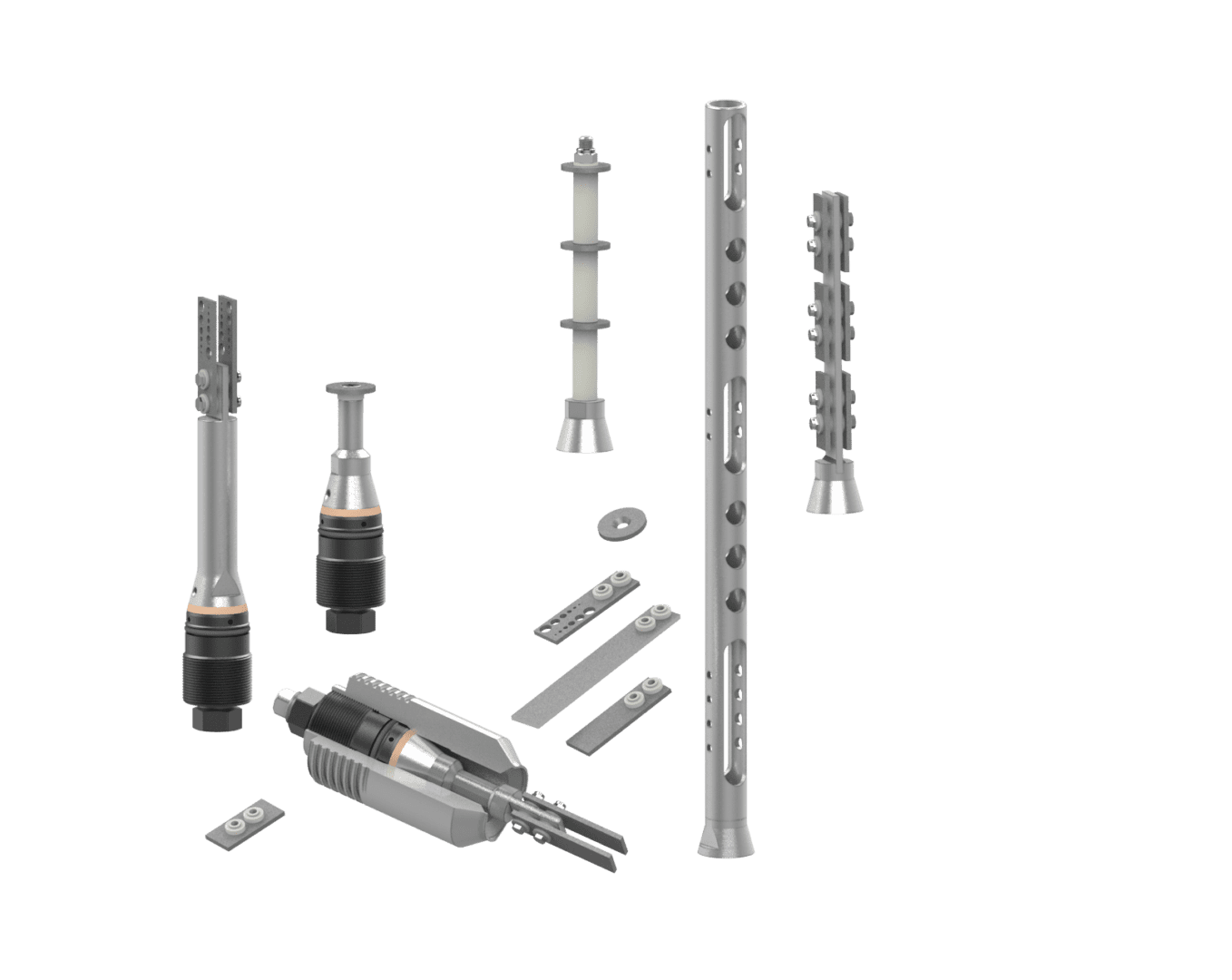

SMARTCORR online corrosion monitoring systems vary significantly in complexity, from simple coupon exposures or handheld data loggers to fully integrated plant process surveillance units with remote data access and data management capabilities. It is advisable to use several complementary techniques rather than rely on a single monitoring method. Real-time monitoring of pipelines, vessels, and other static equipment enables a near-instantaneous appraisal of the corrosivity of produced and transported fluids.

Our PDC drill bits performed best in various conditions:

- The toughest formations oil and gas wells are drilled successfully by our clients

- Unconventional oil and gas wells

- Improve ROP and longer lasting drill bits and also lower costs