What is UGW Technology?

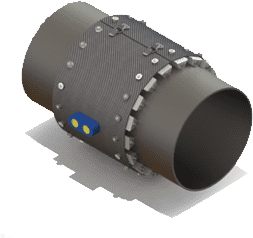

SMARTCORR® UGW technology is an effective way for online nondestructive testing and integrity monitoring of pipelines in various industries. UGW technology can be used to inspect the corrosion or erosion of pipelines and can cover 100% of the wall thickness of pipelines.