What is a Chemical Injection Skid?

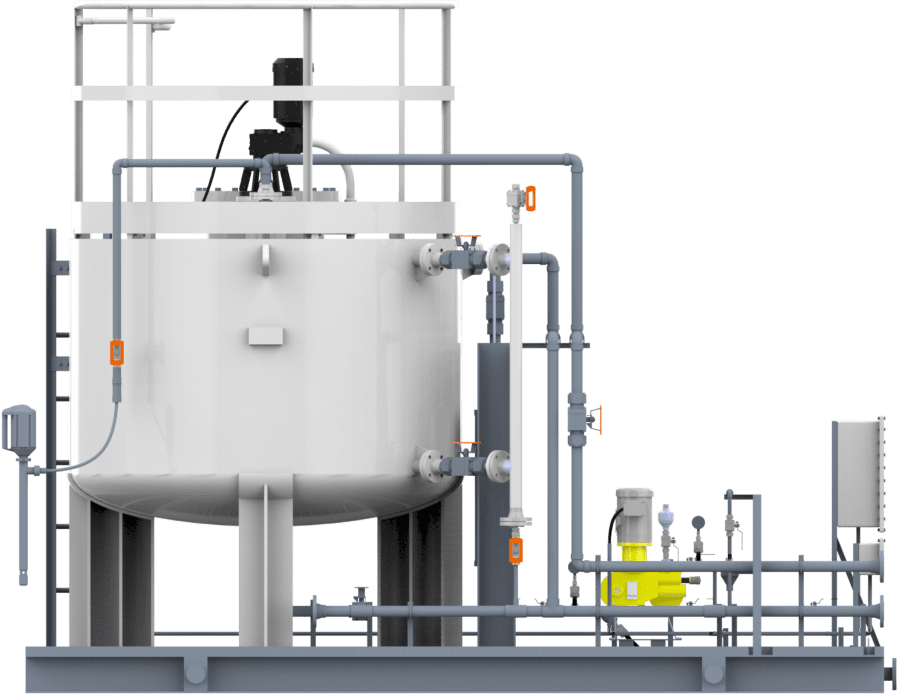

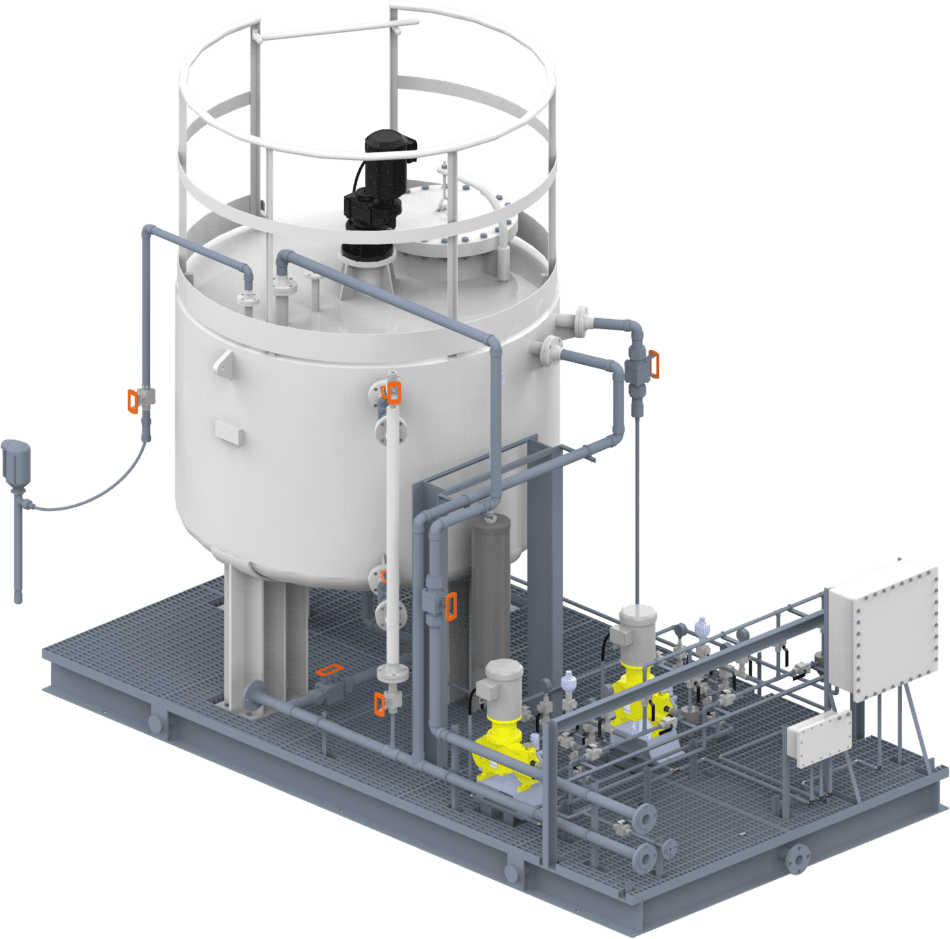

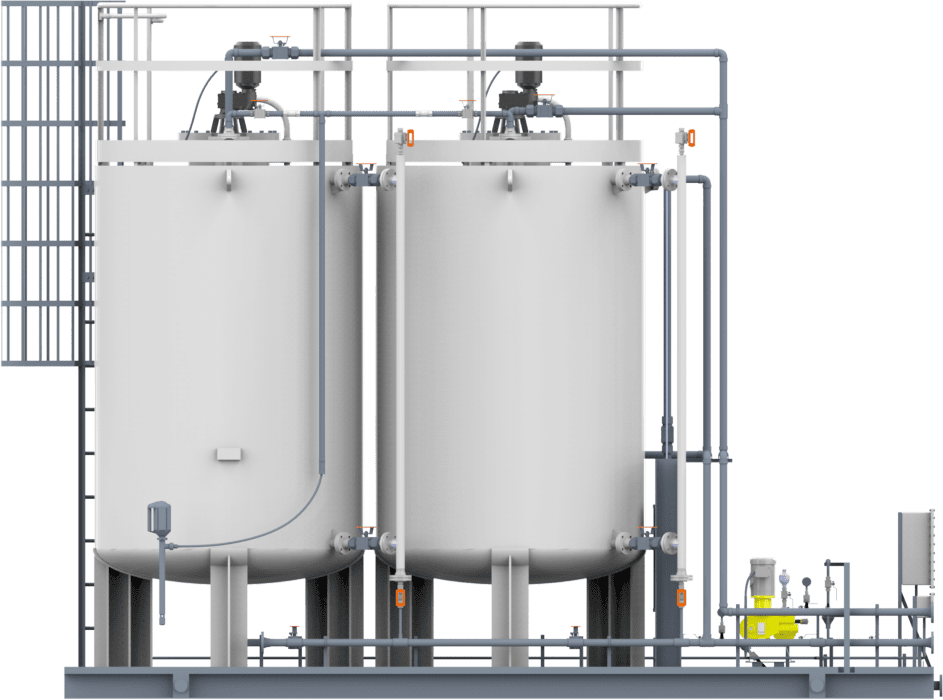

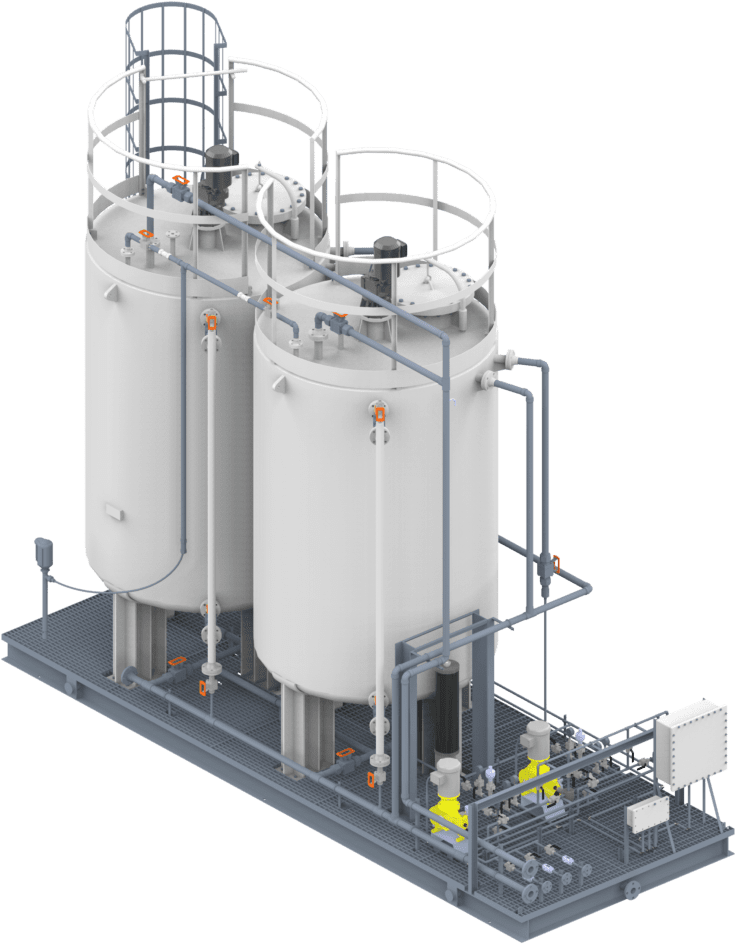

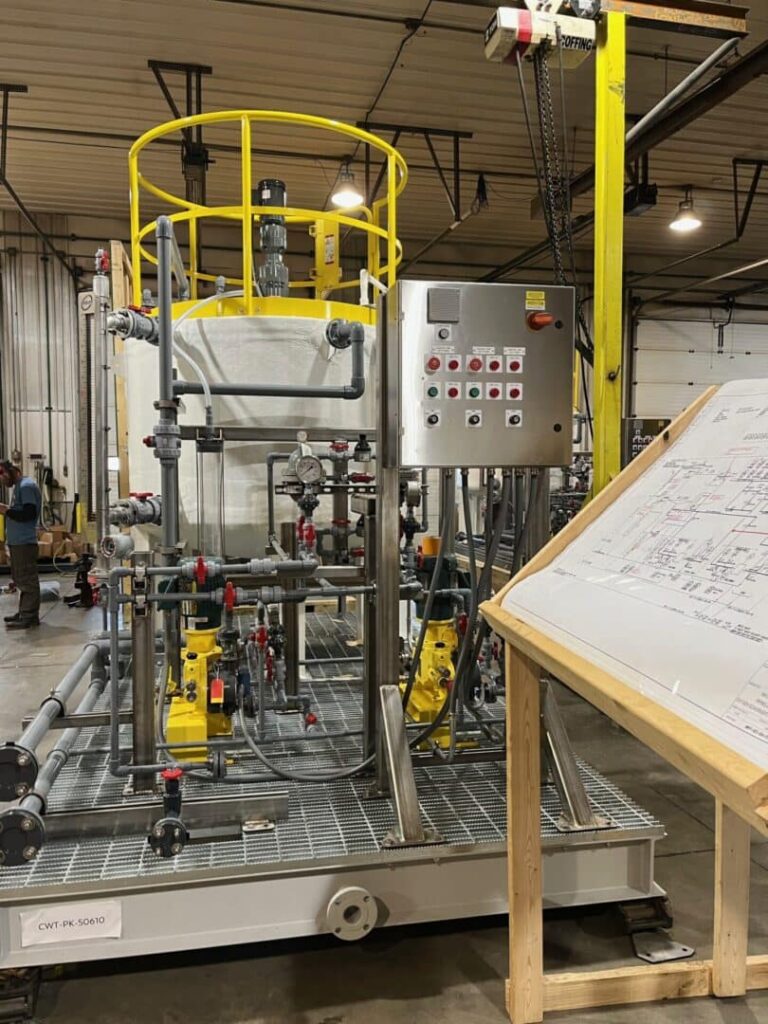

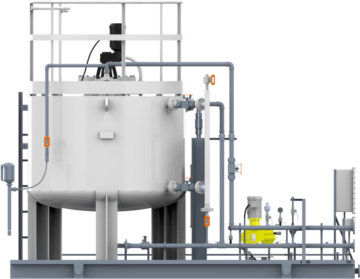

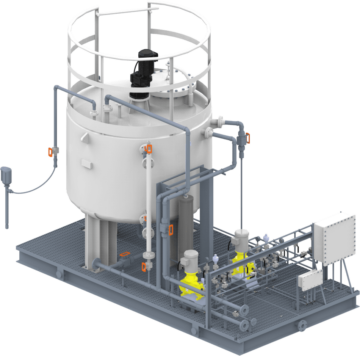

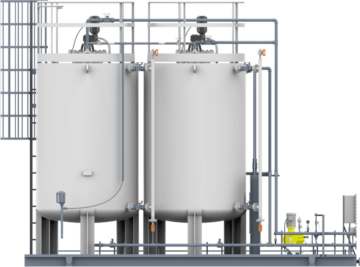

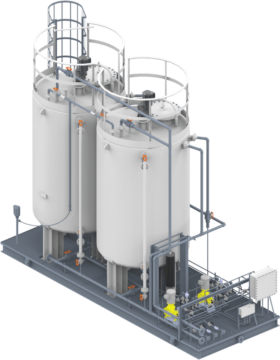

Chemical injection skids are modular pump packages that dose inhibitors into live process streams to stop corrosion and scale before they can affect vital infrastructure. SMARTCORR® chemical injection skids are designed specifically to meet the industrial standards and customers’ requirements and specifications, with components and instruments that are compatible for accurate dosing and operation.

The oil and gas industry uses this equipment for various applications, water treatment, including cleaning wells, protecting pipelines from corrosion, scale build-up, and improving oil recovery. Our solutions are modular, API-compliant and deliver continuous, precise chemical dosing to prevent corrosion, hydrates and scaling. Built on our expertise, these skids can help operators lower their costs as well as their risks.