How it Works

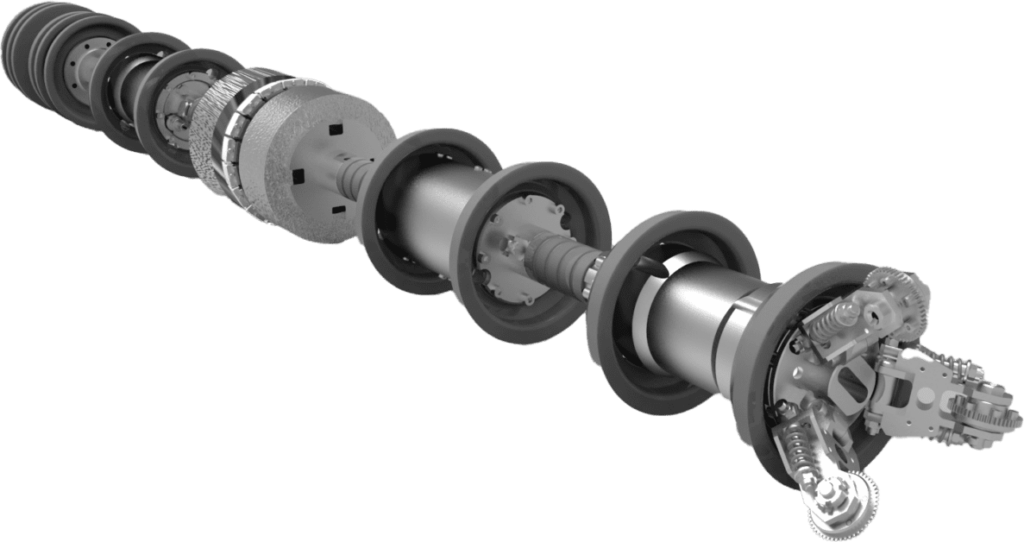

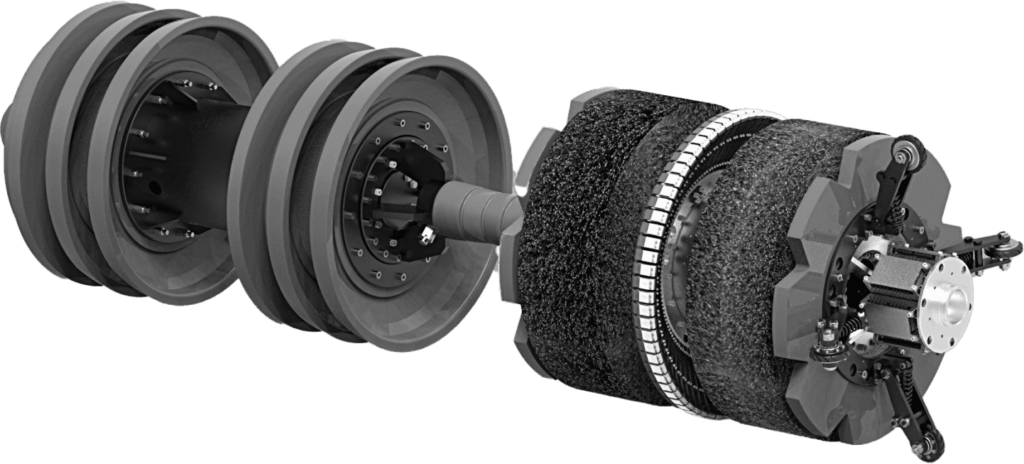

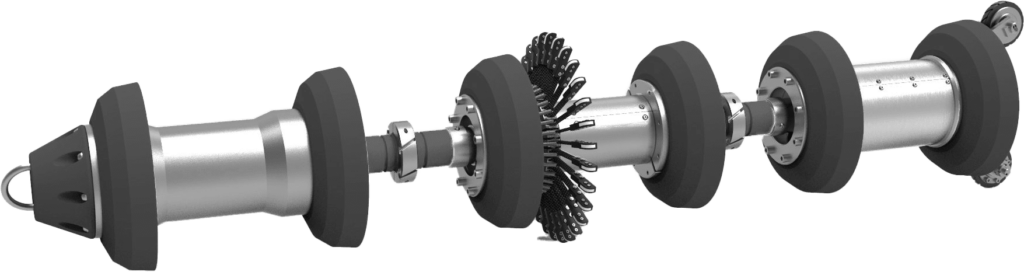

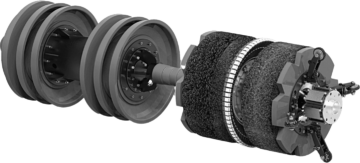

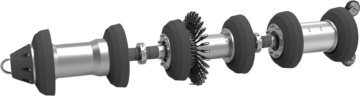

SMARTCORR® provides a range of MFL ILI tools that ensure pipelines remain functional and compliant with all relevant industry regulations. Magnetic inspection theories are applied in high-precision magnetic flux leakage (MFL) in-line inspection tools (ILI). They can run in gas and liquid medium. MFL in-line inspection tools are utilized in the examination and determination of the severity of metal loss in steel pipelines.

The tools can be used for the inspection of pipeline defects, wall changes, wall material changes, internal and external corrosion, and pipe features (pipe hoop, scar, elbow, weld, tees, etc.). They can provide full information on the defects’ area, extent, location, and direction. With the use of these tools, operators in the oil and gas sector can prevent costly equipment failures and ensure the safety of their infrastructure.