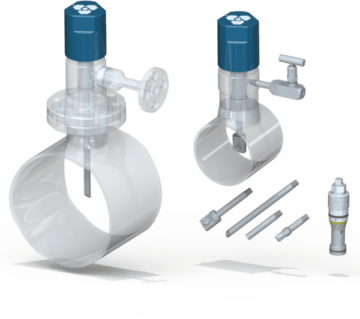

How it Works

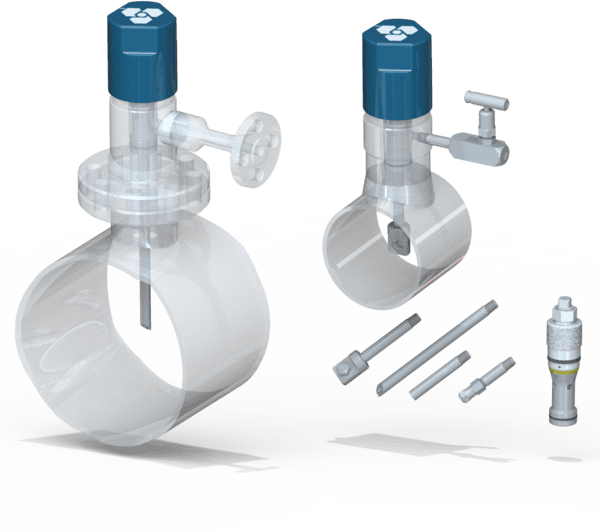

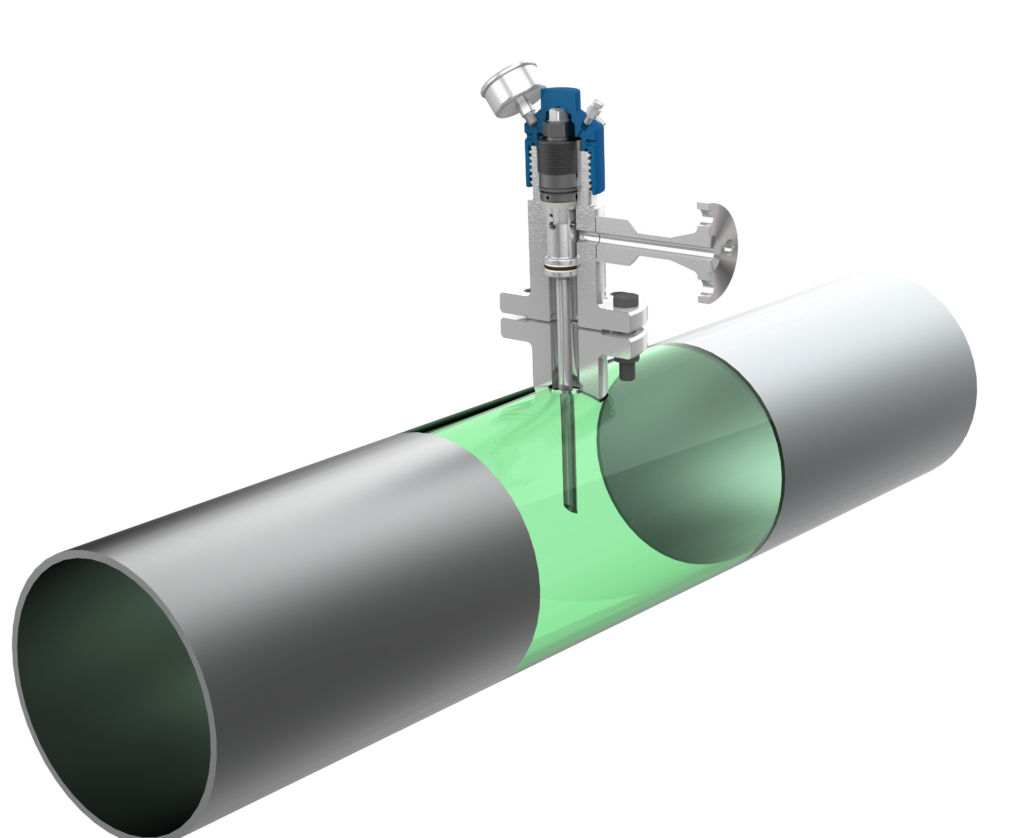

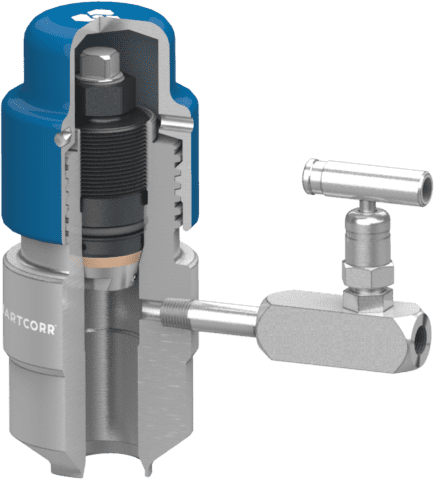

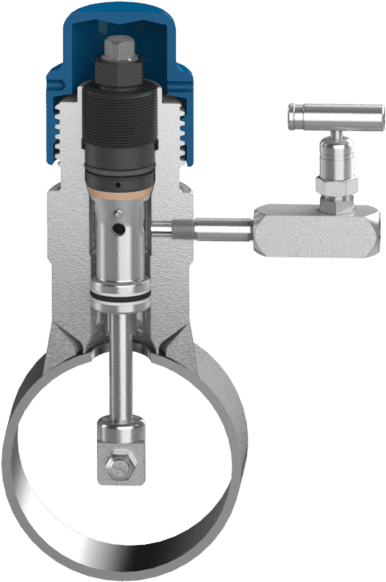

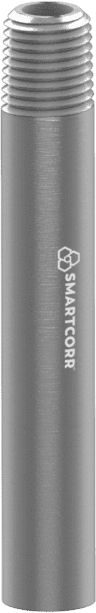

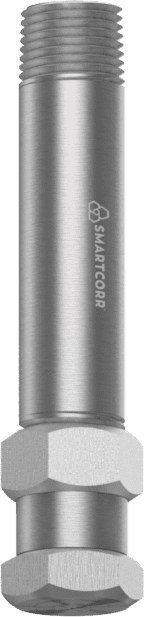

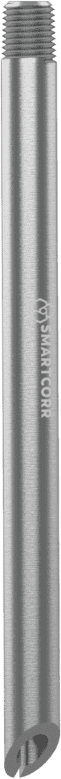

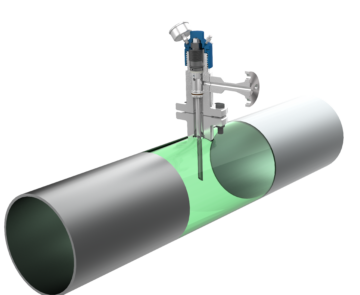

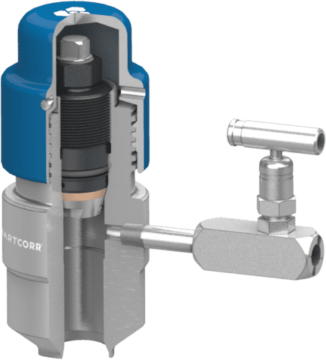

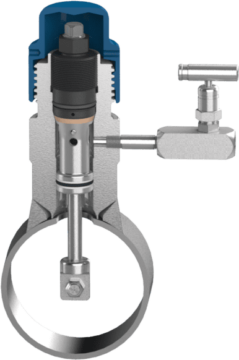

SMARTCORR® offers a wide range of chemical injection and sampling systems as well as the services needed to help you make the most of them. Injection and sampling systems are used across the oil and gas, chemical, and water treatment sectors. This equipment is inserted into pipelines under pressure to either inject chemicals to further the process or take samples of the fluid or medium inside them.

Chemical injection equipment, such as chemical injection quill, tends to be complex due to the various factors that influence its capabilities, such as the pressure differential and the viscosity of the fluid inside the pipeline. Chemical injection systems in the oil and gas industry are a critical component for controlling corrosion and various types of process control. Sampling systems typically are used before testing fluids for oxygen levels, metal ions and other parameters.